● U-section aerodynamic technology

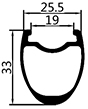

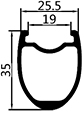

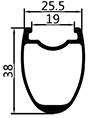

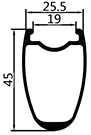

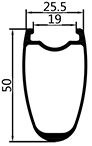

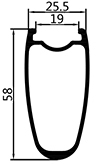

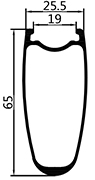

● 25.5mm wide outside, 19mm wide inside

● 33/35/38/45/50/58/65mm depth options

● Standard and ultralight version weight options

Payment:

Paypal, Bank TransferProduct Origin:

ChinaColor:

UD/3K twill (Customized Decal Acceptable)Brake:

Grooved 3K Twill Rim BrakeHole Count:

F-20H / R-24H

The upgraded PRO 26 wide carbon fiber ultralight road 700C series wheels are available in standard and ultralight version weight options.

Rims are tubeless ready: compatible with both tubed and tubeless setups.

Features improve rolling resistance, comfort, traction and reduce the propensity for flat tires.

U-section aero technology design. If you want a fast, deep rim that will set you apart from the competition, the PRO2645/50/58/65 Disc Brake is a great choice.

This is also designed for the experienced cyclist looking for an aerodynamic advantage or the larger rider who wants a really solid wheelset.

FEATURES:

FEATURES:

- U shape design Aerodynamic advantages

- Double wall design, for better strength and stiffness

- Compatible for both normal tube tire and tubeless tire

- Best grooved 3K twill brake surface

- Road disc-brake carbon rims, 25.5mm width

- 33/35/38/45/50/58/65mm depth optional

- 2 years' quality warranty

SPECIFICATIONS

|

Model |

PRO-2633 |

PRO-2635 |

PRO-2638 |

PRO-2645 |

PRO-2650 |

PRO-2658 |

PRO-2665 |

|

Cross Section |

|

|

|

|

|

|

|

|

Sectional Drawing |

|

|

|

|

|

|

|

| Material | T700 & T800 |

T700 & T800 |

T700 & T800 |

T700 & T800 |

T700 & T800 |

T700 & T800 |

T700 & T800 |

| Use | Road | Road |

Road |

Road |

Road |

Road | Road |

|

Type |

Clincher |

Clincher |

Clincher |

Clincher |

Clincher |

Clincher |

Clincher |

|

Tubeless |

Ready |

Ready |

Ready |

Ready |

Ready |

Ready |

Ready |

|

Internal/External Width |

19mm/25.5mm |

19mm/25.5mm |

19mm/25.5mm |

19mm/25.5mm |

19mm/25.5mm |

19mm/25.5mm |

19mm/25.5mm |

|

Depth |

33mm | 35mm |

38mm |

45mm |

50mm |

58mm | 65mm |

|

ERD |

574mm | 570mm |

564mm |

550mm |

540mm |

524mm | 510mm |

|

Standard weight |

460+/-15g | 460+/-15g | 470+/-15g | 480+/-15g | 500+/-15g | 540+/-15g | 580+/-15g |

| Flyweight | 390+/-15g | 390+/-15g | 400+/-15g | 420+/-15g | 450+/-15g | 470+/-15g | 530+/-15g |

|

Standard Limit Flyweight Limit |

110kg/242lbs

90kg/198lbs |

125kg/275lbs

90kg/198lbs |

125kg/275lbs

90kg/198lbs |

130kg/286lbs

90kg/198lbs |

130kg/286lbs

90kg/198lbs |

135kg/297lbs

90kg/198lbs |

135kg/297lbs 90kg/198lbs |

|

Spoke Tension |

115 ~ 130kgf | 115 ~ 130kgf |

115 ~ 130kgf |

115 ~ 130kgf |

115 ~ 130kgf |

115 ~ 130kgf | 115 ~ 130kgf |

|

Max Tire Pressure(with 25C) |

110psi / 7.58bar |

110psi / 7.58bar |

110psi / 7.58bar |

110psi / 7.58bar |

110psi / 7.58bar |

110psi / 7.58bar |

110psi / 7.58bar |

|

Tire Recommended |

25C ~ 35C |

25C ~ 35C |

25C ~ 35C |

25C ~ 35C |

25C ~ 35C |

25C ~ 35C |

25C ~ 35C |

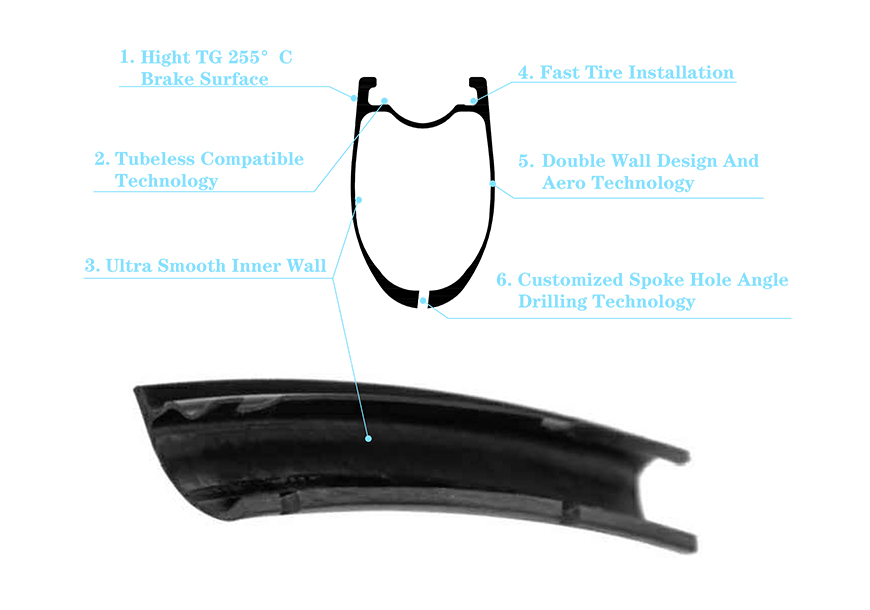

TECHNOLOGY

1. High TG 255°C Brake Surface

High TG resin temperature 255° brake track, solve the heating problem on the rim brake clincher bicycle wheels.

The grooved track helps to evacuate trapped moisture between the brake pad and carbon rim under wet. it bears a higher temperature while braking, but for faster braking heat elimination. More friction, less lever force needed, and shorten about 30% braking distance. More friction to shorten the braking distance.

2. Tubeless Compatible Technology

The bump on the rim bed helps to create a buffer during tire inflation, making the mounting process easier. The bead locks allow for an easy switch between clinchers and tubeless setup.

3. Ultra Smooth Inner Wall

Use specific, thinner, high-pressure air bladders to control the inner wall smoothness, The result is that we could see a very clean and smooth inner wall, which means the carbon fabrics are stretched smoothly and optimized. This could ensure the best strength of the fabrics.

4. Fast Tire Installation

Easy installation and removal of normal tube tires and tubeless tires.

5. Double Wall Design and Aero Technology

We use a double wall design to better control the rim strength and stiffness during layup. Rim profiles are specially designed with aero gains and drag reduction in mind.

6. Customized Spoke Hole Angle Drilling Technology

High-speed CNC machine tools drill carbon fiber rim spoke holes. Customized according to the geometric angle of the hub. Check all drill holes to make sure they are free of burrs.

RIMS FOR EVERY CONDITION

Related Products